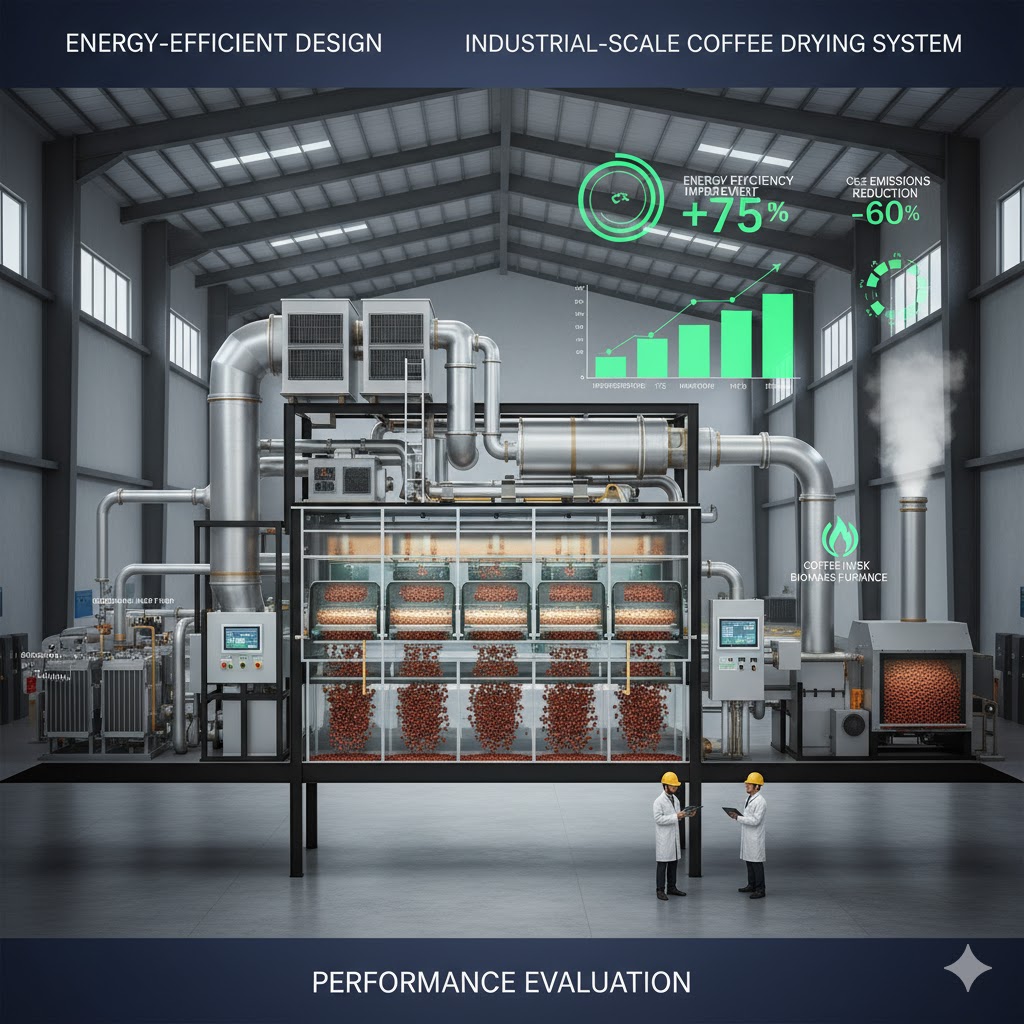

Energy-Efficient Design and Performance Evaluation of an Industrial-Scale Coffee Drying System

Keywords:

Hybrid coffee dryer, Energy and exergy efficiency, Thermal energy storage (TES), Life cycle assessment (LCA), Sustainable coffee production, Carbon emissions reduction, Renewable–fossil hybrid systemsAbstract

This study evaluates the performance of a hybrid industrial coffee dryer integrating solar energy, LPG backup, and thermal energy storage (TES) to enhance energy efficiency and sustainability in large-scale coffee processing. Experimental trials were conducted using a 50 kg capacity system equipped with a flat-plate solar collector, LPG burner, and packed-bed TES. Drying kinetics, energy and exergy efficiency, life cycle assessment (LCA), and product quality were analyzed. Results showed that the hybrid dryer reduced specific energy consumption by approximately 65% (0.85 vs. 2.40 kWh/kg), improved exergy efficiency from 21% to 38%, and lowered carbon emissions by nearly 80% (0.75 vs. 2.80 kg CO₂e/kg). Although drying time increased (9 h vs. 6 h for LPG-only), cup quality improved with higher sensory scores and fewer physical defects. These findings highlight the potential of hybrid drying technology to reduce energy use and emissions while ensuring premium coffee quality, supporting sustainable coffee production in line with global carbon-neutral targets.

Downloads